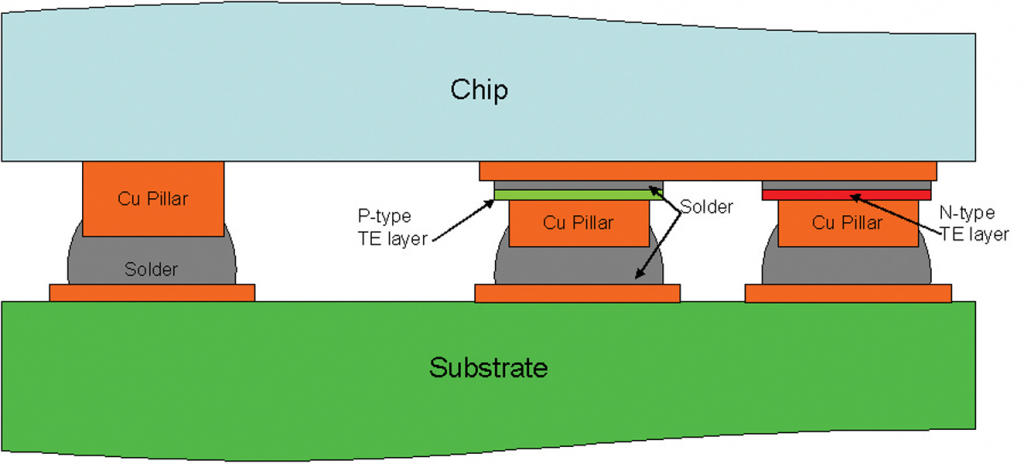

Soldered interconnections typically require cleaning to improve downstream yields and reliability. Cleaning these devices is no easy task. Some devices have thousands of interconnections with pitches as low as 75µm and Z-Axis as low as 15µm. Best-in-Class cleaning process require that the cleaning agent be matched to the cleaning equipment and material compatibility of exposed metallization layers.

Cleaning processes are commonly designed to run aqueous cleaning agents within high throughput aqueous spray-in-air cleaning equipment. The cleaning agents are designed to be processed at a concentration range of 2-8%. To achieve cleaning at these low concentration levels, alkaline builders are formulated into the cleaning agents. To prevent interaction of the cleaning agent with the metallization used within the packaging, Best-in-Class cleaning agents are engineered with materials that do not attack or corrode the exposed metals during the cleaning process.

KYZEN research chemists are experts in designing cleaning materials that rapidly clean soils while not corroding exposed metals during the cleaning process. Improperly built cleaning agents may clean well but commonly attack exposed metallizations. Attacking exposed metallization impact downstream wire bonding, attachment and underfill operations.

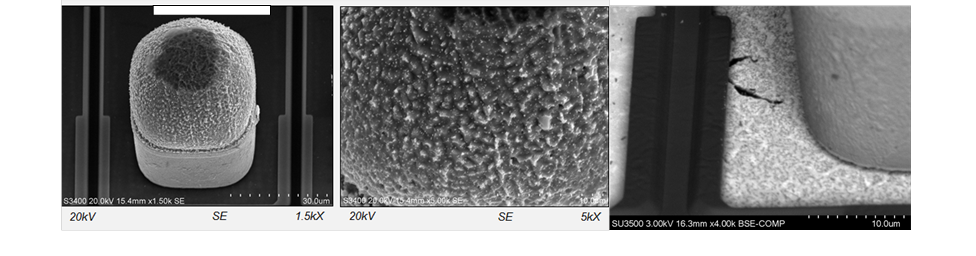

Results of Improperly Designed Cleaning Agents

KYZEN cleaning fluids designed for advanced packaging are engineered with materials that protect exposed metals during the cleaning process. KYZEN also designs process control equipment that allows the customer to monitor cleaning agent concentration and soil loading levels.

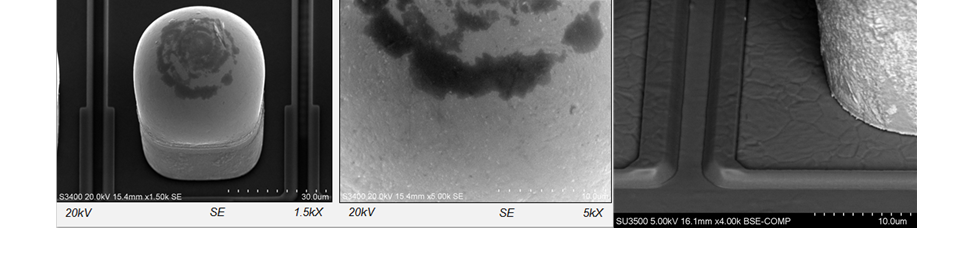

Results of Best-in-Class Cleaning Agents

The optimal design characteristics of the cleaning agents are:

- Low concentration in the range of 1-5% dilution in the wash section of the machine

- No foam at any concentration

- Low COD/BOD/VOC

- Mild saponification to rapidly dissolve harden flux residues

- Low surface tension to wetting, penetration and cleaning of flux residue under CSP, Flip Chip.

- No odor

- Compatibility with dissimilar metals exposed during the cleaning process

- Designed for Cu Pillar Flip Chip Application

- Effectively cleans WS flux residues under high dense die

- Superior metal compatibility on exposed sensitive metals

- SAC, Aluminum and Copper safe

- Lower surface tension

- Designed for removing tough flux residues

- Effectively on all types of packaging such as FC & SiP

- Superior metal compatibility on exposed sensitive metals

- Stable pH & long bath life

- Free rinsing