Manual PCB cleaning is a common need for a variety of reasons, getting the process right is important. Rework and repairs to production assemblies are the most common reasons for manual PCB cleaning on the bench outside of an automated process. However, cleaning may also be needed after hand placement of BGAs, connectors or other surface mount components.

Manual PCB cleaning is a common need for a variety of reasons, getting the process right is important. Rework and repairs to production assemblies are the most common reasons for manual PCB cleaning on the bench outside of an automated process. However, cleaning may also be needed after hand placement of BGAs, connectors or other surface mount components.

Whether you are using an aerosol can or a pump dispenser at your rework station, making sure you have the right chemistry is key. KYZEN’S CYBERSOLV product line was developed to address benchtop PCB cleaning needs.

KYZEN’s Benchtop Cleaning Procedure will walk you through best practices when cleaning at the bench is necessary.

4 Basic Steps for Benchtop PCB Cleaning

Take the appropriate steps to remove flux residues and not risk contaminating the complete assembly during the cleaning process.

Step 1 – Spray small amount of cleaning solvent on the board wetting the residue.

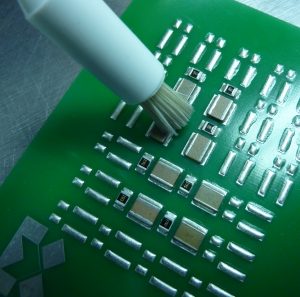

Step 2 – Gently scrub the area with a brush.

Step 3 – Rinse with fresh cleaning solvent allowing residue to flow freely from the printed circuit board. Keep in mind, chemistry flows where gravity leads.

Step 4 – Air dry or wipe with a swab or lint free wipe.

One of the critical keys to any cleaning process is the final rinse and benchtop manual cleaning is no exception. It is important to note that fresh material is vital no matter what cleaning fluid you use. Residues must flow off the printed circuit board to prevent redeposition and cross contamination. Finally, it is best to wipe with a swab or lint free wipe to absorb the remaining cleaning fluid. Residues left on the board can redeposit elsewhere and cause future board failure.

| Rosin Flux | OA / Water Soluble Flux | Pb-Free | No-Clean | Uncured Adhesives | |

| CYBERSOLV C141-R* | ✓ | ✘ | ✓ | ✓ |

✓

|

| CYBERSOLV C8882 | ✓ | ✓ |

✓

|

✓

|

✓

|

*Available in Bulk and Aerosol Packaging