The Science Lab

Protecting What’s Important: Rust Prevention Awareness

Protecting What’s Important: Rust Prevention Awareness

The spring season is officially here and that means change is in the air (literally). Flowers bloom after a long winter, leaves turn from brown to green, and the cold air gets warmer. For the most part, this change is welcomed; however, when it comes to your ferrous metal parts, change is the last thing you want to happen. Rust can occur in any season, but with return of humidity levels in the spring, it is the perfect time for corrosion to arise like the returning flowers. It goes without saying that corrosion brings about a number of issues, increased rejection rate (rusted parts that need to be thrown away) being one of them. To protect your parts and avoid losing money, it’s time to start thinking about how you can prevent this unwelcome change now.

If you are not sure where to begin, don’t worry. We can point you in the right direction. KYZEN offers a line dedicated to corrosion inhibitors for all types of manufacturing and storage needs. No matter what material you work with, these products provide dry film protection for short-term and long-term requirements. To learn about these products and more, simply click the link below or get in touch with one of our Cleaning Experts today.

Download our Corrosion Prevention Cutsheet now!

What All Modified Alcohol Users Should Know

What All Modified Alcohol Users Should Know

If you are working with a vacuum degreaser, chances are you are using either a hydrocarbon or modified alcohol solvent. Of the two, it can be said that modified alcohol has a bigger audience because it requires very little monitoring yet yields high-quality results. (Not to mention it also cleans both polar and non-polar soils, doesn’t use water, is VOC free, and is low cost.) No matter if this is the first or even twentieth time you’ve used the solvent, there are always ways to ensure you are using modified alcohol to the best of its ability.

Our cleaning experts have taken a deeper dive into this topic a few different ways so that they can present you with the best information. And the best part is they are giving it to you for free!

- Our cleaning expert Ethan Mueller has taken the time to compile everything you need to know about modified alcohol into a helpful user guide. In this guide, you will learn about routine testing, maintenance, quality control considerations, and more. It heavily revolves around our popular modified alcohol-based solvent METALNOX M6386 but also includes general information as well.

- Wayne Raney, KYZEN’s Process Engineer, recently gave a broad yet short overview about all things modified alcohol in his latest Tech 2 Tech session. You can not only watch the video on the topic, but also download the Questions and Answers that may cover your own questions.

If you have any questions for our experts whether it is about modified alcohol or cleaning in general, don’t hesitate to let us know!

Download the paper here or Watch Wayne Raney’s Tech 2 Tech event on this topic here

Meet Your Regional Manager

Jack Reinke – Southeast Regional Manager

Jack Reinke – Southeast Regional Manager

Born and raised in Chicago, IL, Jack currently resides in Atlanta with his wife of 39 years while his three daughters are in various states either working on their education or settled in their careers. He has been with KYZEN for 24 years in April with an additional 12 years at other companies meaning he has over 35 years of experience in the cleaning industry! He states of all the companies he has worked at, KYZEN has been the best company he has ever worked for. Jack graduated from Michigan State University with a science degree in Resource Development/Environmental Science. In his spare time, you can find Jack fishing. He’s actually the Secretary of the SMT Space Coast Chapter and helps coordinate the annual Offshore Fishing Adventure! Some fun facts about Jack: 1) He worked with KYZEN’s Vice President Tom Forsythe before they both worked together at KYZEN. 2) He makes sure to keep in touch with his siblings no matter where they are. 3) He was once addicted to Hooters wings but says his grease tolerance has dropped. Be sure to reach out to Jack if you have any questions! He is more than happy to help.

Will Sweet – Midwest Regional Manager

Will Sweet – Midwest Regional Manager

Originally from Lexington, KY, Will has been with KYZEN for almost three years representing the Ohio Valley area. He received his undergrad degree from Hanover College and graduate degree from the University of Kentucky. In his free time, he enjoys being active outdoors and taking up new hobbies such as golf and pool. He also enjoys watching movies and considers himself a “superhero nerd.” His love for the outdoors does not fall far from the tree! He comes from a very active family and has many memories of his parents hauling him, his brother, and teammates to various sporting events in their minivan. Will actually played in the 12-Year-Old Cal Ripken World Series. He has also been to Disney World 18 times and his favorite food is chocolate chip cookies. His dedication to his customers does not go unnoticed. If you ever have any questions for Will, don’t hesitate to reach out!

Our Lab Is Your Lab

Our Lab Is Your Lab

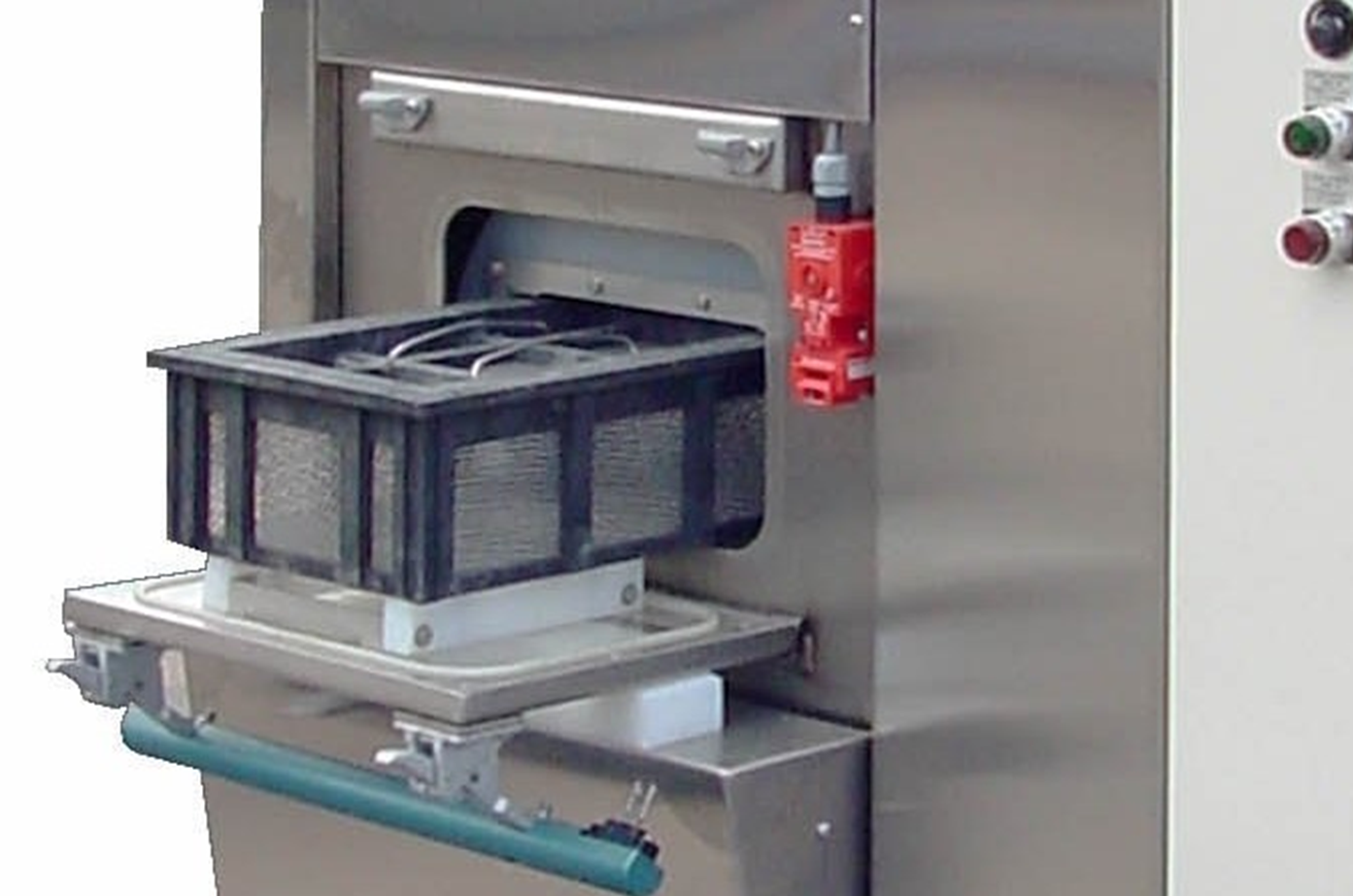

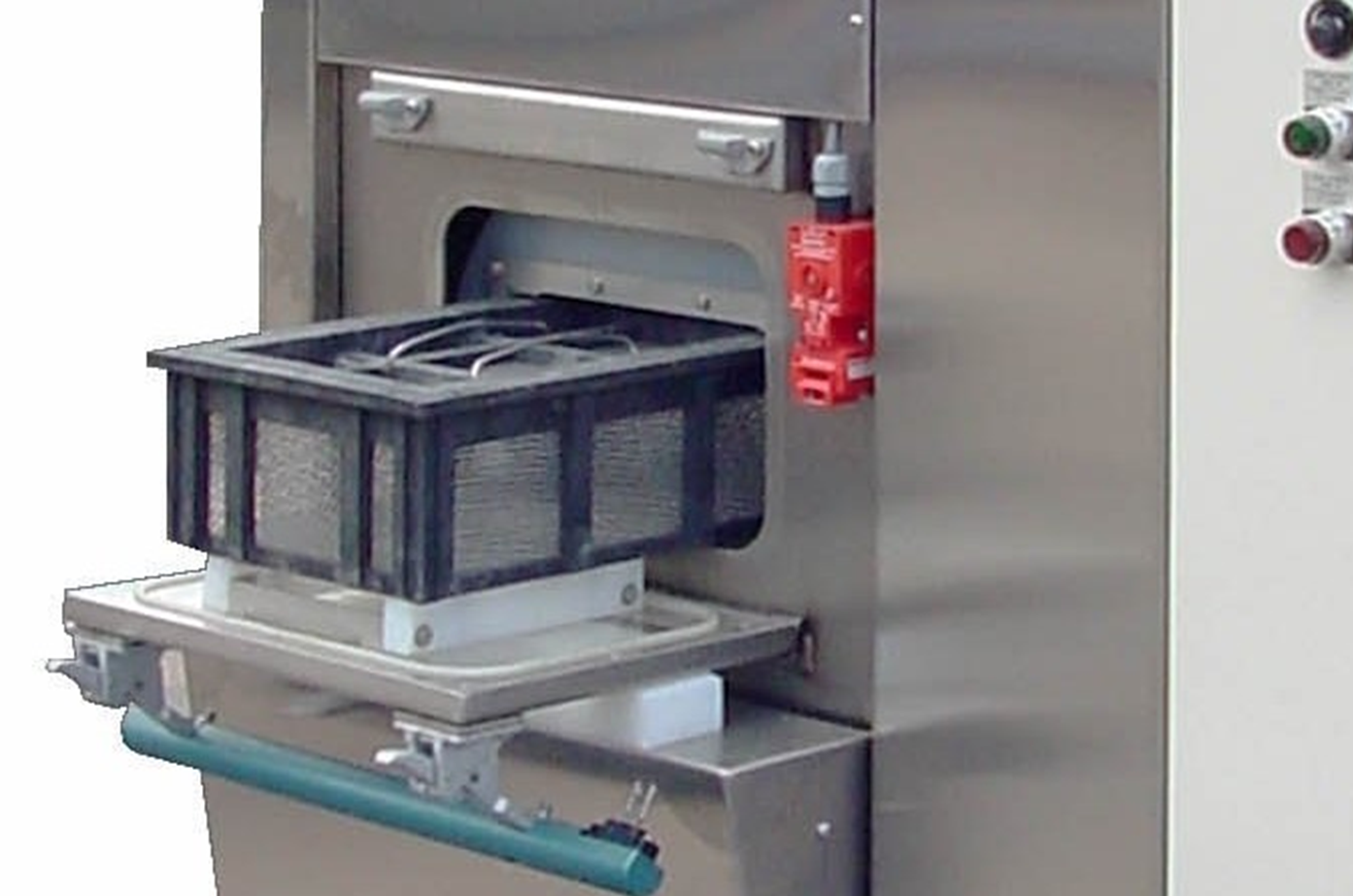

One thing you can count on when operating a production line, is that challenges will present themselves at inopportune times. At KYZEN, we are equipped with experts and tools to help you through those challenges and tend to your process care needs. As our slogan suggests, we truly believe that science and care go hand in hand. We would love to take this opportunity to share and offer the many different lab services that could assist with your product testing and cleaning needs.

Our analytical and application lab services contain many resources that you can utilize to improve your process or determine if there is a potential mishap that needs attention, should you be experiencing inaccurate results or activity. Take a look below at what our labs can offer today so that they may help you tomorrow.

- Analytical Lab Services

- Our services include wash bath analysis and wash bath profiling, FTIR analysis, gas chromatography analysis, Ion Chromatography testing, SIR testing, Millipore testing, scanning electron microscope inspection and SEM/EDS analysis, as well as R.O.S.E testing.

- Atmospheric chamber testing

- During this testing, each metal part is checked for rust or corrosion, and electronic circuit boards are checked for failures related to moisture and extreme conditions. This testing option creates tightly controlled, programmable hot/cold and humid atmospheres that may induce corrosion, rust and/or failure for clean parts for any end-use.

- Process development and validation

- We help you develop a cleaning process that fits your floor space, your budget, and your end result requirements. We work with you at no charge to design the best cleaning method, beginning from process development through validation of outcome. This allows you to evaluate solutions without interrupting your production or generating new waste at your site.

- Wash tank conditioning/maintenance

- Delivering the right amount of chemistry at the right time and properly conditioning the wash tank is key. It reduces the cost of ownership while increasing production by providing consistent, reliable performance, and is also good for the environment.

We can also come to you to help with…

- Your Process Start-Up

- Ensures you gain the knowledge and training you need to effectively utilize your purchase. Our technically trained salespeople and/or engineers will help you with your initial fill, optimize the process parameters of the machine, show you how to check and maintain the concentration, and remain with you until the first batch of clean parts come off the line

- Perform an On-site Process Audit

- KYZEN’s engineering and field support team will come to your facility and review chemistry usage, rinse water quality, nozzle pressures and alignment, exhaust balancing, amperage draw for motors and blowers and more. If you would prefer an alternative option to our onsite services, we offer a free cleaning process health checkup conference call to deliver specific process improvement recommendations.

Whatever your cleaning process goals are, we are here to help! Please reach out to any of our cleaning experts for more information on how you can take advantage of these services and more. You may also learn more about these services in greater detail here.

Quality: A Prevailing Attitude

Tom Forsythe, Executive VP

KYZEN Corporation Nashville, TN, USA

Quality is personal. Each of us has a personal definition for the meaning of quality. After all, regardless of our profession, every day we encounter food, services, goods and people all of whom we hope are of good quality. Of course, we in the business of making things often have a more focused definition. Does this good or service meet the needs and expectations of a customer who will be willing to pay for it?

30 or so years ago when our company KYZEN was founded, one of the goals was to be a “quality shop.” I don’t think KYZEN was unique in choosing that as one of its goals, some others being survival as well as being a fun place to work were on that list as well. As we went about defining and meeting that “quality shop” standard, we encountered many opportunities and challenges. At first, our thoughts focused on the challenges: quality testing, manufacturing procedures, safety of our supply chain and product development focused on creating products that meet the needs and expectations of our customers.

This strikes me as the norm for most companies pursuing a quality reputation, especially in their early days. The challenge of course is defining the standards of performance and behavior that will be accepted as quality by the marketplace. Once you define quality, how does a company embrace that quality standard? How high should one set the bar for quality: is “good enough” acceptable, or should one aspire for something more?

It is easy to write concepts and goals down on paper. At least it is easier to write them down than to follow through with the actions required for a commitment to quality. What happens when achieving that aspirational standard has a cost, or even more telling what happens when a product or service is OK but, in all honesty not quite good enough. What choice gets made? Ship it or try again? Go to market now, or go back to the lab bench and continue inventing? It is often said quality is about getting the little things right. Colin Powell, a former Secretary of State and Army General here in America said it more eloquently:

“If you are going to achieve excellence in big things, you develop the habit in little matters. Excellence is not an exception; it is a prevailing attitude.”

-Colin Powell

No wonder General Powell has been so successful. Excellence is a prevailing attitude, and most certainly excellence embodies the concept of quality ~ exceptional quality. Looking back over our now 30 plus years in business, I can clearly see where a handful of decisions long ago created the prevailing attitude that set KYZEN on its never-ending journey seeking excellence focused on the convergence of science and care.

One event stands out clearly in my mind as both validating our core self-image, id for the psychology majors in the audience, and for helping us realize that the journey to excellence is not a solitary one but rather the wisdom, effort and care of many, both inside and outside your organization that helps you persevere on the quest.

Back in the 90s, the early 90s, the forward-thinking companies could see the writing on the wall about chlorofluorocarbons (CFCs) and their imminent demise. They had been used for many things due to their high safety ratings for we the human species. However, we learned that while safe for humans, they were not so good for the ozone layer, which was itself pretty important for humans never mind the rest of the flora and fauna of planet earth. So, the world changed how it did many things, and one of those things was how we accomplished cleaning processes in the industrial, non-consumer part of the global economy.

To read the full article, click here.

Protecting What’s Important: Rust Prevention Awareness

Protecting What’s Important: Rust Prevention Awareness What All Modified Alcohol Users Should Know

What All Modified Alcohol Users Should Know Jack Reinke – Southeast Regional Manager

Jack Reinke – Southeast Regional Manager Will Sweet – Midwest Regional Manager

Will Sweet – Midwest Regional Manager  Our Lab Is Your Lab

Our Lab Is Your Lab

Connect with our Cleaning Experts at the following events.

Connect with our Cleaning Experts at the following events.