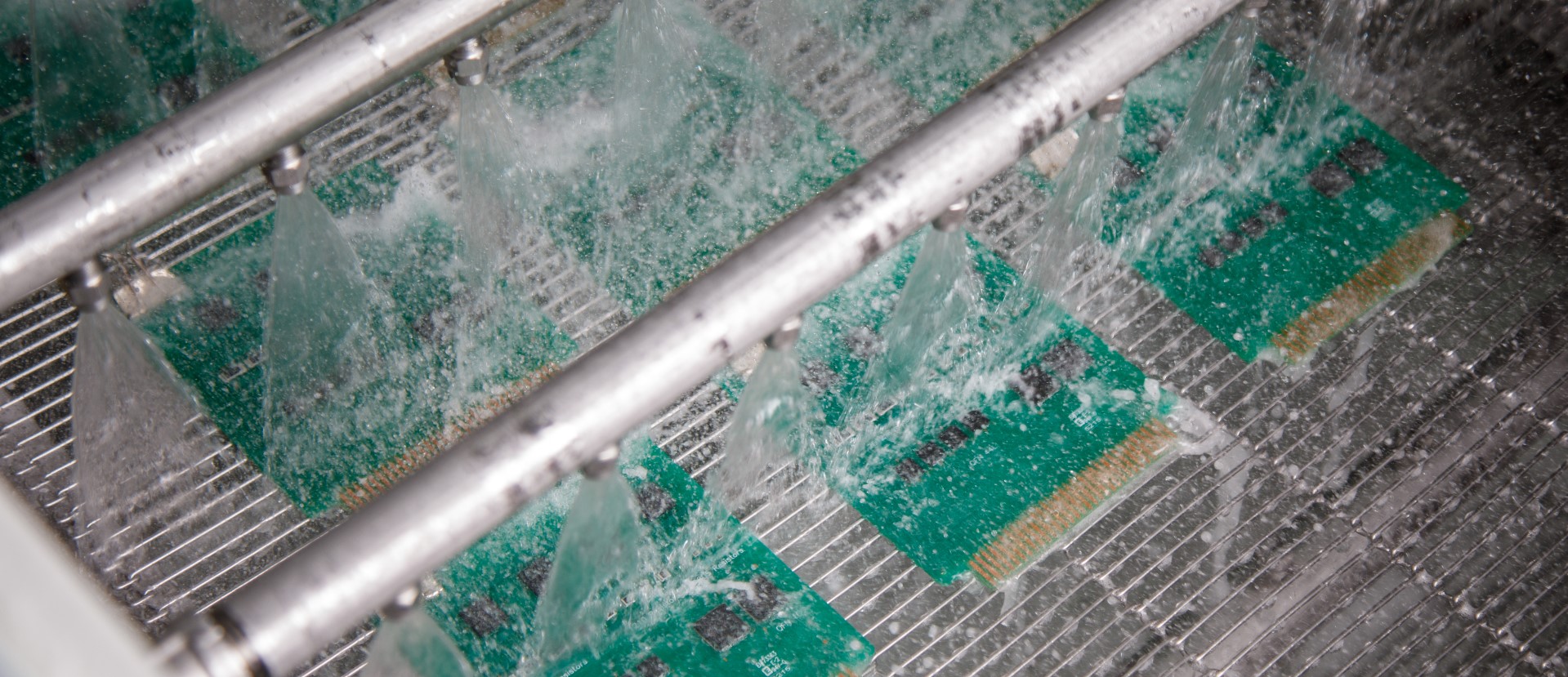

KYZEN offers an array of PCB cleaning agents that are formulated to take advantage of an Inline washer’s powerful combination of high flow, impact energy, and deflective forces. These conveyorized machines provide the highest production throughput and faster fluid penetration under low gap components like challenging QFN’s.

Batch cleaning machines are designed to efficiently wash, rinse, and dry assemblies in a small footprint. Groups of electronic assemblies are sealed inside the machine where they are typically washed, rinsed, and dried in a single main process chamber, hence the name “Batch”.

These processes completely immerse the product being washed, so that the cleaning agent fully contacts every surface of the device. Most immersion applications utilize either Ultrasonic energy or Spray -Under -Immersion (SUI) forces to circulate the fluid and apply mechanical energy to the substrate surface.

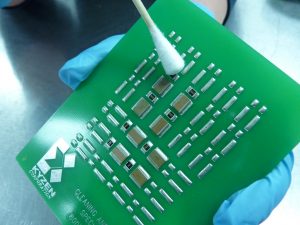

Cleaning at the benchtop is a very common practice in electronics manufacturing operations. While often the final crucial step in cleaning PCBs (e.g. rework, repair and prototype), manual cleaning is accomplished in a variety of ways. KYZEN has a complete line of topical cleaners to address each situation.

The vapor degreasing cleaning process is integrated around an engineered solvent composition that dissolves (matches up) with the soil(s) being removed. The engineered cleaning fluid is often a blend of solvents which behave like an azeotrope, forming a constant boiling system at a specific temperature range.