The Science Lab

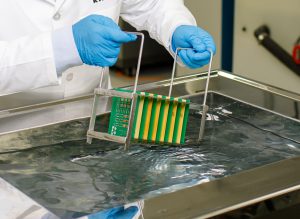

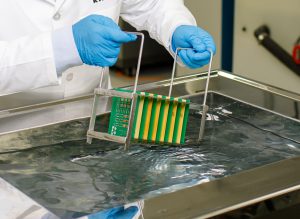

How to Optimize Your Aqueous Inline Process

How to Optimize Your Aqueous Inline Process

One of the initial steps in the implementation of any successful cleaning program is understanding how to consistently apply the cleaning agent to the soil matrix while maintaining long-term control of the manufacturing process. Several factors contribute to the stability and continued success of any aqueous cleaning process.

They all begin with the proper set up and adjustment or “Base Lining” of the inline cleaner. This simple often overlooked exercise will go a long way to ensuring long-term success. Such factors and exercises are crucial to ensuring your aqueous inline is at peak performance but understanding where to begin can be challenging. Luckily, our KYZEN cleaning experts have taken the time to provide a step-by-step guide to ensure your system is optimized from start to finish.

To gain access to this exclusive content, simply click here. And as always, if you have any questions for our team, don’t hesitate to let us know!

Cleaning Solutions for Every Process

Cleaning Solutions for Every Process

No matter what product or process you are working with, KYZEN has the solutions that could work for you. For over 30 years we have been helping customers enhance their process from start to finish. While we have worked with and developed many chemistries over the years, you might be wondering what our top picks are currently. We’ve got you covered!

Here is a small overview of our recommendations for PCB, Stencil, and Maintenance cleaning:

PCB Cleaning

AQUANOX A4727: An electronics assembly cleaning solution that provides exceptional results when cleaning printed circuit boards and advanced packaging assemblies. Its advanced technology gives a stable pH, superior risibility, and predictable compatibility throughout its long bath life.

AQUANOX A4382: A near-neutral range pH chemistry designed with superior cleaning efficacy with great material compatibility on surface mount assemblies. It is formulated as a concentrate and designed to work in spray-in-air aqueous cleaning machines. A4382 is low in odor and contains no hazardous materials. It has a wide material compatibility window and is specifically designed for use on printed circuit board hardware.

AQUANOX A4625: AQUANOX A4625 is a highly dispersive cleaning agent designed to clean electronic assemblies in spray-in-air cleaning equipment. A4625 is effective on greater than 90% of the solder pastes in production today and is commonly used to clean lead-free and no-clean flux types but will also clean water-soluble soils.

CYBERSOLV 141-R: This product dissolves rosin and low residue flux residues and then readily evaporates after the cleaning application. CYBERSOVLV 141-R is designed for bench-top cleaning needs and is ideally suited for cleaning through-hole and SMT electronic assemblies, connectors, cables, and hybrid circuits. The product is excellent for spot cleaning flux and is commonly used to clean solder joints following hand soldering.

Stencil Cleaning

KYZEN E5631: KYZEN E5631 is designed to be used at low concentrations and ambient temperature in stencil cleaning processes including spray-in-air, understencil, and ultrasonic systems. E5631 was formulated with the worker and environment in mind and is a cost-effective solution that quickly and efficiently cleans all types of raw solder paste flux from stencils and A-side misprints.

CYBERSOLV C8882: CYBERSOLV C8882 is a solvent-based stencil cleaning fluid specifically designed to clean solder paste, uncured SMT adhesive and flux residue from stencils, mis-printed PCBs, stencil tools and printing squeegees. C8882 can be used in automated understencil wipe processes, hand-wipe, and ultrasonic cleaning systems as well as spray systems designed for solvent.

Maintenance Cleaning

KYZEN E5322/E5325: KYZEN E5322 is engineered to perform off-line maintenance cleaning of your wave solder effectively and efficiently, reflow oven systems, and associated tooling. KYZEN E5325 is used in spray-in-air applications to effectively and efficiently perform off-line maintenance cleaning to remove even the most difficult fluxes and solder pastes from pallets, wave solder fingers, reflow oven parts and associated tooling

CYBERSOLV C8502/C8508: CYBERSOLV C8502 is specially formulated to quickly remove all types of flux residues from wave solder fingers, reflow oven surfaces and general electronics production equipment. CYBERSOLV C8508 is an aqueous based cleaner for reflow ovens and general equipment maintenance. This product effectively removes adherent residues outgassed during the reflow-soldering step of surface mount assemblies that includes solder paste activators and functional additive build-up.

To download this information for yourself, click here. Additionally, keep in mind that these are only a few of our top chemistries, but we have several other products that might be even better for your specific needs. We invite you to browse the full list here.

Meet Your Regional Manager

Jason Schwartz – Southern Regional Manager

Jason Schwartz – Southern Regional Manager

Originally from Cincinnati, Ohio, Jason has been with KYZEN for 8 years. While he has been a Regional Manager for various locations since he began, he currently lives in Nashville, TN and is the Southern Regional Manager. Jason has always had an interest in chemistry and graduated from the University of Cincinnati with a B.S. in Chemistry. In his spare time, Jason enjoys golfing, rugby, and cheering on the Cincinnati Reds Baseball team. He also loves to travel and has been to a dozen countries on 4 continents (although interestingly he’s never been to Canada or Mexico!) and hopes to be able to expand that number soon. Another fun fact is that Jason has won Product Finishing’s 40 Under 40 Award after being nominated for his hard work. If you have any questions for Jason, do not hesitate to reach out. He will be more than happy to help!

Introducing Our New Tech 2 Tech Packages

Introducing Our New Tech 2 Tech Packages

As you may or may not know, in July of 2021, our Tech 2 Tech program officially turned one! Once we hit this milestone, we thought it was only right to take a step back and look at the program to see how it could evolve (as all great things do in time). After a lot of planning, we are happy to share with you the next phase of the Tech 2 Tech program: Tech 2 Tech Packages!

So how was this created and what does it mean for you? Essentially, we examined the program as a whole and noticed we have a lot of content out there now. To be exact, we have over 50 educational videos since the premiere of the program. We wanted to find a way that everyone (including you) could benefit from all this knowledge, so we decided to group certain videos together into little bundles that focus on a specific topic (ex: Bath Life, Cleaning Basics, Corrosion Protection, etc.). We geared these topics for both the Electronics and Metal Finishing industry.

This now means that instead of scrolling through our library to see if we have presented on a certain topic, it’s now bundled together, served up and ready to be watched. The packages also include any relevant documents pertaining to the sessions so you don’t have to dig for those either.

If you haven’t been able to explore the packages yourself, now is the time! Additionally, if you are new to our Tech 2 Tech program, you can learn how it works by viewing our latest commercial and register for one of our sessions today at tech2techbykyzen.com. Don’t hesitate to let us know if you have any questions!

View Our Tech 2 Tech Packages Here

25 Years of Process Care Services

25 Years of Process Care Services

For 25 years, KYZEN has proudly supported customers all over the globe with our process care services. These services help process engineers manage, monitor, and improve performance. Below are a wide array of services KYZEN offers.

Find out which product might be the right fit for your process by viewing what we have to offer below:

Analytical Lab Services: Our labs are equipped with the latest analytical equipment and staffed with a team of highly trained chemists to provide support to our customers worldwide. The Analytical Labs provide our customers with unparalleled laboratory services to see them through a wide range of problems. Our testing services include Wash Bath Analysis, FTIR Analysis, GC (Gas Chromatography) Analysis, IC Testing (Ion Chromatography), SIR Testing, Millipore Testing, R.O.S.E. Testing, and more.

Contract Cleaning: The contract cleaning service allows us to assist customers with a variety of issues to avoid cleaning system downtime, corrosion issues on metal parts, flux removal needs on no-clean parts, customer rejects with current cleaning process, and much more.

Atmospheric Chamber Testing: Atmospheric Control Chamber creates tightly controlled, programmable hot/cold and humid atmospheres that may induce corrosion, rust and/or failure for clean parts for any end-use. KYZEN offers this testing in response to the growing concern among industries about accelerated environmental, reliability and corrosion issues.

New Process Start-Up: The process of switching chemistries over to a KYZEN chemistry can seem daunting. However, we ensure that you gain the knowledge and training you need to effectively utilize your purchase. Our technically trained salespeople and/or engineers will help you with your initial fill, optimize the process parameters of the machine, show you how to check and maintain the concentration, and remain with you until the first batch of clean parts come off the line. We will also help remove any trace of the former product from your machine before KYZEN chemistry is fully installed.

On-Site Process Audit: By verifying and trending important operating parameters, you can detect problems early and prevent issues that may affect production and/or quality over time, ultimately providing better quality products for your customers. The engineering and field support team at KYZEN will come to you to review chemistry usage, rinse water quality, nozzle pressures and alignment, exhaust balancing, amperage draw for motors and blowers and more. If an on-site visit is not needed, we also offer conference call options with members of our clean team.

Process Development and Validation: With this service, KYZEN has made themselves available to help develop and validate your cleaning process from the beginning. We can recommend a cleaning process that fits your floor space, your budget, and your end result requirements. We also work with potential customers at no charge to design the best cleaning method, beginning from process development through validation of outcome.

Risk-Free Trial: Determine your cleaning process, verify, test and implement are the 3 steps we want you to follow before committing to a product or process. Our “try before you buy” concept is something that KYZEN believes is crucial. Our risk-free trial includes cleaning your product (from circuit boards to automotive and aerospace metal parts and everything in between) in our award-winning application laboratories where we can thoroughly evaluate a broad range of process solutions. We’re available to help setup and validate the process at your site – anywhere in the world!

Wash Tank Conditioning/Maintenance: KYZEN developed this particular service to combat the struggles with productivity and various processes. Delivering the right amount of chemistry at the right time and properly conditioning the wash tank is key to getting the most value. This proven approach reduces the cost of ownership while increasing production by providing consistent, reliable performance. Plus, conserving water and minimizing chemical use benefits the environment as well.

To learn more about our services, visit here.

How to Optimize Your Aqueous Inline Process

How to Optimize Your Aqueous Inline Process  Cleaning Solutions for Every Process

Cleaning Solutions for Every Process Jason Schwartz – Southern Regional Manager

Jason Schwartz – Southern Regional Manager Introducing Our New Tech 2 Tech Packages

Introducing Our New Tech 2 Tech Packages  25 Years of Process Care Services

25 Years of Process Care Services  Connect with our Cleaning Experts at the following events.

Connect with our Cleaning Experts at the following events.