The Science Lab

The Importance of Remanufacturing Cleaning

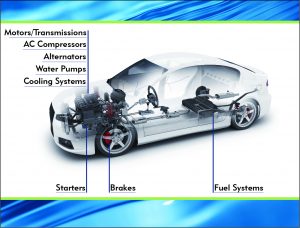

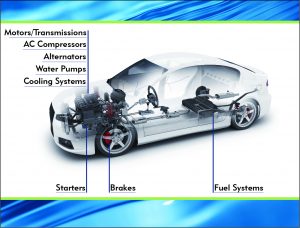

Remanufacturing is defined as the process of returning a used product to at least its original performance level with a warranty that is equivalent to or better than that of a newly manufactured part. There are several benefits to remanufacturing, including:

- Economical method to maintain vehicles

- Quick method to get equipment back in operation

- Performs in the same manner as the original parts

- Reduce raw materials consumption (carbon footprint) vs original production of new parts

- Reduces GWP (Global Warming Potential) from fugitive emissions generated during original manufacturing

Upon receiving engines, transmissions, cores, and other miscellaneous components, the initial action is cleaning. The attached soils must be removed to disassemble and inspect parts. Poor cleaning can require additional time/reruns to achieve desired results as well as affect work area housekeeping. Difficult to remove soils such as burned-on oils and carbon, oxidation, and grime are quickly removed without damage to the parts when using KYZEN METALNOX products.

These products are formulated for maximum cleaning power while being environmentally safe. Furthermore, they are designed to provide exceptionally long bath life which lowers operational costs! Take a look at what products KYZEN offers for remanufacturing by downloading this brochure or learn more by watching Ethan Mueller’s Tech 2 Tech session on this topic here.

Corrosion Protection for Brass Metals – A Case Study

Cleaning Requirement:

A large manufacturer needs to remove screw machine oils from a variety of brass screw machine parts and provide three months of corrosion protection in open-air warehousing after cleaning.

Situation:

The large manufacture of brass screw machine parts consists of pipe/tubing fittings for applications including hydraulic, pneumatic and refrigeration. The parts are cleaned in a large number of Ransohoff Immersojet washers which incorporate spray-in-air, spray under immersion, and basket rotation. They range in size from single to six basket systems, and all incorporate a wash – rinse – dry process.

The customer had experienced a very costly corrosion problem during the summer of 2006 when black corrosion pits developed on finished goods inventory after leaving the customer’s plant. As a result, the customer switched to a neutral pH cleaning chemistry which only partially cleaned the parts leaving a protective coating on the parts. The two resulting problems were (1) the oily parts did not appear as bright and clean as competitors’ similar parts, and (2) the residual oil layer was difficult to control and resulted in sporadic corrosion problems.

Parts were test cleaned using various chemistries at KYZEN’s Nashville, TN Technical Center where the customer’s cleaning process was simulated. The cleaning/corrosion problem was duplicated using cleaning chemistries similar to those which the customer had used.

- Parts cleaned in this neutral pH chemistry were left oily but did not corrode during accelerated humidity chamber testing.

- Parts cleaned in mild alkaline chemistries displayed no signs of residual oil, but corroded severely in the humidity chamber, very similar to what the customer was experiencing with the alkaline chemistry they had used previously.

The product which proved to successfully remove the machining oil and provide protection for the brass parts was METALNOX M6310, a mild alkaline cleaning chemistry that contains corrosion inhibition components that are effective on brass, copper and aluminum. Several months of testing at KYZEN’s Technical Center provided assurance for both the customer and KYZEN to begin converting the Immersojet washers to METALNOX M6310.

Results and Conclusions:

The customer implemented M6310 in all 16 Immersojet Washers. During a 3-month period of time, KYZEN conducted bi-monthly humidity chamber accelerated corrosion tests on parts cleaned at the customer’s plant, with no failures. No parts were returned from the field for corrosion. The customer claims parts are cleaner and brighter, and they are now more competitive in their marketplace. M6310 demonstrated improved bath life and increased cycles between chemistry changes from approximately 150 to 180.

To read more case studies like the one above, visit our E-Knowledge center today. Additionally, learn how you can take advantage of our services like the ones mentioned in this study by visiting here.

Meet Your Clean Team

Debbie Carboni – Product Line Manager – Electronics

Debbie Carboni – Product Line Manager – Electronics

Debbie Carboni is the Global Product Line Manager for KYZEN’s Electronics segment. She has been a friend of the KYZEN team since she started her career as one of the industry partners working for H2O Products, followed by 5+ years at Technical Devices as the Eastern Regional Manager. Debbie grew up in Flagstaff, Arizona, when she was hired as the sales manager for H2O products.

While she learned a lot, she was ready for a new adventure and started working for Technical Devices. In 2007 she became a North American regional manager at KYZEN, and later on was promoted to Global Product Line Manager. With holding the highest record for number of cell phones in the shortest period of time (23 androids in 15 months), most of KYZEN is also fully aware of Debbie’s electric personality that seem to short circuit electronics which come in close contact.

Debbie has 2 children, Dominic and Ali, and they are known by many not only within KYZEN, but most of the Electronics Industry. She currently lives outside of Philadelphia with her children, extremely loving and supportive husband Tom, of almost 23 years, puppies, cats, and once in a while a stray animal or kid for short periods of time. You will see her at most Electronics events, always with a smile on her face, where most people welcome a Debbie Hug.

Feel free to reach out to Debbie with any cleaning questions you may have!

Chuck Sexton – Global Product Line Manager – Industrial

Chuck Sexton – Global Product Line Manager – Industrial

Chuck joined KYZEN in 2002 and since then has been heavily involved in the development of KYZEN’s industrial products business. He has worked in the industrial parts cleaning industry in both Sales and Process Engineering, since 1979. Chuck holds a bachelor’s degree in Chemical Engineering from the University of Illinois, and an M.B.A. from the University of North Florida.

Chuck enjoys the business travel associated with his position. This allows him the chance to see many parts of the world, and to develop close relationships in many countries. Regional Managers are astutely aware of the need to make a certain number of Starbucks stops when Chuck is traveling with them. A few fun facts about Chuck:

- He takes a couple of skiing trips per year, usually in Colorado.

- His son, Michael, will be graduating from Law School at Michigan State University this May.

Feel free to reach out to Chuck with any questions you may have!

Steer to Safe Cleaning Solvent Alternatives

In 2020, the EPA released a Chemical Risk Evaluation for several traditional degreasing solvents including TCE, nPB, Perc and MC. These reports indicated potential health risks to workers and recommended that action be taken to find replacements. The new guidelines are due in two years from official release dates. The EPA must release a final ruling that may either restrict or ban the use of these solvents. That means now is the time to start thinking about alternatives.

At KYZEN, we made the decision to get ahead of this change and assist our customers in navigating to a more efficient and safer cleaning process by offering alternatives for various processes such as:

- Vacuum Degreasing

- Aqueous Cleaning

- Industrial and Electronics Vapor Degreasing

There are many choices to consider when it comes to selecting cleaning processes and chemistries. Our METALNOX and MICRONOX product lines obtain alternatives that could be beneficial replacements for your process.

For more information on products offered and how this potential change affects your cleaning goals, click here.

Get Subscribed to Cleaning

Over the years, KYZEN has had one overarching goal in mind: to provide helpful information that can enhance your cleaning process no matter what industry. In the 30+ years we have been in business, this still remains true. We understand that finding solutions to your cleaning challenges can be laborious, especially with all sorts of information floating out there. At KYZEN, we make it easy to find the answers you need which is why we are proud to announce the launch of our YouTube channel.

There are different ways that people can consume information, visually and vocally being the most popular methods. For the many visual learners out there, we have taken the time to compile video playlists that host information provided by our experts in the field. From best practices on stencil cleaning to best ways to protect your metals, the channel is updated frequently with informative and educational videos and even includes insight on how KYZEN operates.

To stay up to date on all things cleaning, be sure to subscribe to our channel and get alerted every time we post a new video!

Debbie Carboni – Product Line Manager – Electronics

Debbie Carboni – Product Line Manager – Electronics Chuck Sexton – Global Product Line Manager – Industrial

Chuck Sexton – Global Product Line Manager – Industrial