The Science Lab

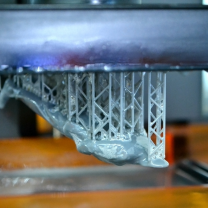

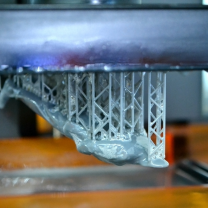

Additive Manufacturing

Additive manufacturing is rapidly becoming a growing and prominent sector in the manufacturing world. Over the course of the past 40 years, we have seen additive manufacturing become increasingly common, easier to use, and more affordable to implement. These technological advances have allowed 3D printing to move from prototyping to production in many industries, especially the dental aligner industry.

With the advancements in printing technology, new challenges and questions have arisen. In particular post-process cleaning has not scaled in the same way that the printer technology has. Many companies still use IPA to clean uncured resins. This method works well in the prototyping phase, but IPA is a very flammable solvent. While easy to use on a small scale, large amounts of flammable liquid on your factory floor present a health and safety hazard. Luckily, KYZEN can offer you a safe and effective solution (water-based or solvent-based) to remove resins and contaminants without harming sensitive 3D-printed parts and molds.

KYZEN 3D5420 is an aqueous post-process resin cleaner that has proven effective in removing a variety of uncured resins and contaminants from stereolithography (SLA) 3D printed parts. This cleaning solution is an excellent alternative to IPA and TPM solvent cleaning processes. Another option to replace IPA is KYZEN 3D5701, which is a solvent post-process resin cleaner. We pride ourselves on creating safe and effective solutions that do not compromise on clean.

If you have any questions about how these solutions could work for you, click here to learn more!

Why You Should Care About Maintenance

Maintenance is an important part of everyday life, your car, your lawn, and your body just to name a few. When referring to manufacturing, maintenance is crucial. Taking the time to keep your machines and facility clean and running smoothly saves time and money but will ensure a safe and efficient working environment. As the summer months approaching, we wanted to go over some of the reasons maintenance is so important.

The first reason is your ability to maintaining quality control. Complying with industry standards and meeting customer expectations, you don’t want to find a quality issue on your hands. Regular maintenance of equipment, such as pH meters, conductivity meters, and other analytical instruments is necessary to ensure accurate readings in your washer and provide consistent product quality.

The second reason is equipment reliability. The machines that we use are complex and typically expensive. Keeping a regular maintenance program on schedule ensures that your equipment is operating efficiently, it minimizes the risk of failure, avoids downtime, and helps evade costly repairs.

The next reason is environmental compliance. While most cleaning solutions are very safe to use, when combined with your soils they often can require thoughtful handling or processing prior to disposal. Proper maintenance of equipment, such as wastewater treatment systems, ensures that these chemicals are effectively treated before being released into the environment.

To sum it all up, by regularly maintaining your production equipment (including your parts washer), you will avoid costly repairs, minimize downtime, and extend their lifespan. Basically, a regular maintenance schedule will save you, your company, and your employees – time, money, and energy. Taking these preventative steps today can save you from issues tomorrow.

For more in-depth information about maintenance take a look at our Tech2Tech series – here!

Meet The Clean Team

Chelsea Jewell – Applications Lab Manager

Chelsea Jewell is KYZEN’s Application Lab Manager and has been with KYZEN for the past 11 years. She is from Rogersville, Alabama and went to school at Auburn University and Austin Peay State University where she graduated with a degree in Chemical Engineering Technology.

Chelsea is married to Bobby, another one of KYZEN’s finest, and they have one son named Bay. Some of Chelsea’s hobbies include horseback riding (both jumping and mounted archery), reading, and working on their farm! On the farm they have two horses, a dog, cat, gecko, and coming soon….chickens!

As the applications lab manager, Chelsea brings her years of chemical experience and cleaning knowledge to the role. She evaluates and develops the best cleaning solution for your problem. During her tenure at KYZEN, she has helped to develop several successful cleaning products that are used in the field around the world. Chelsea is known for finding solutions when others may give up.

Reach out to Chelsea with any process cleaning challenge you might have. We are confident that if she doesn’t have the answer, she will find one!

Carolyn Leary – Analytical Lab Manager

Carolyn Leary is KYZEN’s Analytical Lab Manager/ SDS Coordinator and has been with KYZEN for over 20 years. She was born and raised in Wisconsin, but has lived and worked in Kentucky, Iowa, California, and Arkansas before settling down in Tennessee in 1996. Her parents and one of her sisters still live in Wisconsin so she likes to make it back to visit.

Carolyn went to the University of Wisconsin-Stevens Point and graduated with a degree in Chemistry. She’s been married to her husband, John, since 1990 and have two children together. Her daughter Cassie is married to KYZEN’s own James Perigen. Her son is also married since 2018. No grandkids…yet.

Carolyn loves to garden and will give about any craft a try at least once. She also enjoys taking a nice cruise and has even had the chance to hold a sea turtle!

As the Analytical Lab Manager/ SDS Coordinator Carolyn brings a wealth of knowledge and expertise to the lab. With over 20 years at KYZEN she has spent years making sure that our processes are at the top of their game! With new technology and information available, Carolyn keeps us running at top speed.

Feel free to reach out to Carolyn with any questions you might have!

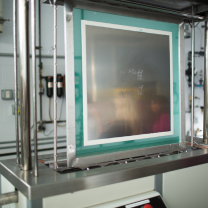

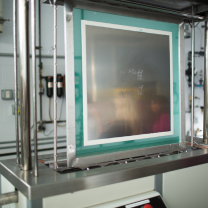

Applications Lab

KYZEN prides itself on making award winning cleaning chemistries along with the perfect cleaning solution for your specific needs and situation. Our Applications Lab is exactly where those two goals come together. Our team of cleaning experts makes your cleaning problem their cleaning problem and won’t stop until they find the best answer for YOUR cleaning challenge. The applications lab is also fully equipped with a variety of cleaning machines to simulate just about any cleaning process in the industry today. Customers often visit with their parts to try out different processes rather than disrupting their onsite production, this allows our customers to find the perfect fit to meet their cleaning requirements. All of the KYZEN Application Labs worldwide have both electronics assembly and metal parts cleaning capabilities. The equipment on-site includes:

– Spray-in-Air (batch and in-line)

– Vacuum Degreasing

– Vapor Degreasing

– Ultrasonic Immersion

– Conveyorized In-line

– Cabinet Spray Washer

– DuoSolvent Processes

– Programmable Controlled Environmental Chamber

It doesn’t matter if the cleaning problem is big or small…our applications lab finds a solution that works best for your needs. To learn more about the applications lab click here!

Analytical Lab

The KYZEN Analytical Lab is truly where science and care converge. Not only is our analytical lab filled with all the latest equipment, but we are also staffed with a team that is enthusiastic about supporting our customers’ needs worldwide. The KYZEN Analytical Lab quality checks EVERY KYZEN product after it is blended and before it is packaged into drums and pails for shipment to our customers. They are the gatekeepers of maintaining the high-quality standards we are known for and helping our customers meet theirs. We have a full staff of chemists and lab techs to analyze our products in use for bath life, soil identification and to assist in making sure your process is running smoothly and efficiently. They also are a large part of our research and development team as KYZEN makes new products.

Our analytical lab offers a wide variety of services to meet whatever needs our customers may be looking for like:

– Wash Bath Analysis

– FTIR Analysis

– Gas Chromatography Analysis

– Ion Chromatography Analysis

– SIR Testing

– Millipore Testing

– SEM Inspection and SEM/EDS Analysis

– R.O.S.E. Testing

No matter what issue you may be facing, our team members are ready to find the best solution for YOU. Our KYZEN Clean Team will collaborate with you to determine what is the best process for your business and to keep you running at full speed. To learn more about our Analytical Lab click here!

Connect with our Cleaning Experts at the following events.

Connect with our Cleaning Experts at the following events.