Back end wafer bumping requires a flux compound to join the solder bump to the metalized pads. Wafer cleaning flux residues following the bumping process is commonly done in immersion and spray-in-air cleaning tools. Best-in-Class wafer cleaning agents are matched to the flux residue and cleaning tool. Properly engineered wafer cleaning agents do not attack exposed metals and render the wafer free of organic and ionic residues.

Wafer Bumping Cleaning Process

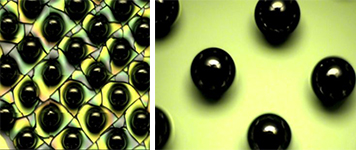

As the bump pitch becomes smaller, removal of process residues becomes more critical and more challenging. Best-in-Class wafer cleaning agents dissolve organic and inorganic residues that are present after the wafer bumping process. Following the cleaning process, the wafers are rinsed with high purity deionized water so that the cleaned wafers may be prepared for follow on packaging.

- Oxygenated cleaning agent designed to remove organic and inorganic residues

- Compatible with exposed metallizations

- Works in immersion, centrifugal and spray cleaning tools

- Renders a wafer free of ionic and inorganic residues