Rapidly evolving electronics manufacturing technologies make it possible for devices to run powerful, high-speed functionality utilizing smaller, even microscopic components, built on wide, sophisticated spans of materials. At the same time, reliability standards have been dramatically raised, shedding light on the importance of advanced electronics assembly cleaning chemistries, processes, and services. As even many consumers know, contaminants and flux residues left on circuit assemblies can corrode during operation and even cause products and devices to fail.

Rapidly evolving electronics manufacturing technologies make it possible for devices to run powerful, high-speed functionality utilizing smaller, even microscopic components, built on wide, sophisticated spans of materials. At the same time, reliability standards have been dramatically raised, shedding light on the importance of advanced electronics assembly cleaning chemistries, processes, and services. As even many consumers know, contaminants and flux residues left on circuit assemblies can corrode during operation and even cause products and devices to fail.

Flexible to your cleaning reliability needs

KYZEN is the global leader in advanced electronics assembly cleaning technologies consistently converging science and care in the engineering, development and delivery of electronics manufacturing cleaning products and services for improved reliability.

KYZEN leads the market in innovation, pioneering new electronics cleaning technologies in advance of manufacturing processes. When critical elements in your process change, we change with them to suit your cleaning reliability needs with the highest levels of compatibility with metals, plastics, and elastomers.

KYZEN provides solutions for all these areas and more:

- PCB Defluxing Solutions

- OA (Organic Acid), RMA (Rosin Mildly Activated), and NC (No Clean) Flux Removal

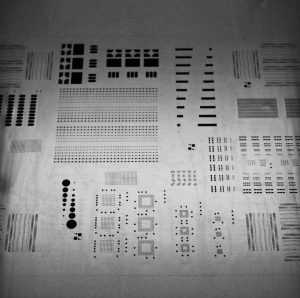

- Stencil and Misprint Cleaning

- Maintenance Cleaning

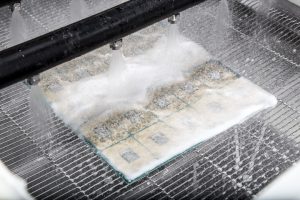

- PCBA Cleaning & Assembly Process

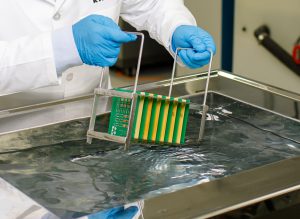

- Ultrasonics and Immersion Cleaning

- Wave Solder Fingers & Dispensing Needles

- Flip Chips / CMOS / BGAs

KYZEN is the renowned trailblazer in the development of flux removal chemistries, defluxing processes, process analytics and data science technologies for cleaning electronics.

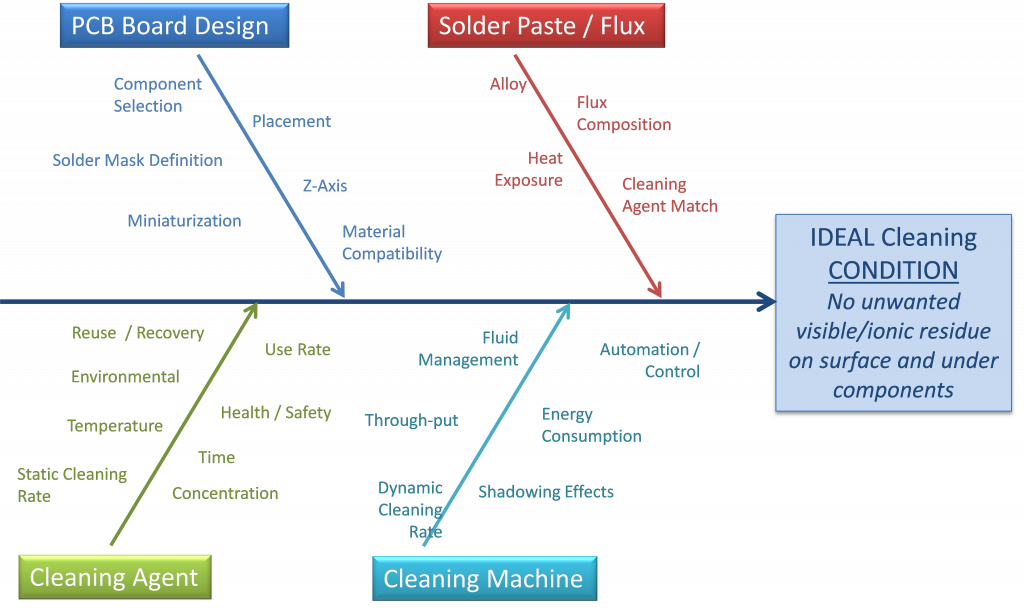

A successful electronics cleaning process requires consideration and integration of the following factors shown in this diagram: