Maintenance plays an important part of any manufacturing process. Keeping your EAC equipment running correctly is essential to ensure you are performing to the best of your ability and extend the life of your capital equipment investment.

Maintenance plays an important part of any manufacturing process. Keeping your EAC equipment running correctly is essential to ensure you are performing to the best of your ability and extend the life of your capital equipment investment.

KYZEN offers an array of powerful, fast-acting cleaning chemistries. CYBERSOLV and KYZEN branded products are specifically formulated for your process maintenance need such as wave solder fingers and pallet cleaning, reflow oven maintenance, wash tank descalers and defoamers as well as other preventative and general maintenance cleaning tasks.

Safe, easy process maintenance cleaning

Routine maintenance is a crucial part of ensuring reliable, high-yield production processes. In today’s time-pressured work environment, scheduling those maintenance activities is often a challenge because most require taking that machine off-line and interrupting valuable production time.

You need process optimization and advanced cleaning technologies that not only work fast but are easy to use and safe for personnel and the environment. In many cases, this process optimization starts with making sure your equipment is operating properly.

For over 30 years, KYZEN’s team of knowledgeable product formulators has refined our industry-leading Maintenance and Tank Conditioning products for:

- Reflow Oven Maintenance: flux build-up can disrupt your profile and lead to re-deposition.

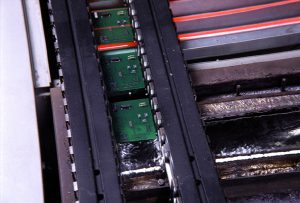

- Wave and Selective Soldering Applications: pallets and fingers are repeatedly exposed to flux build-up.

- Tank Conditioners which include:

- Descalers for soil build-up on heaters and wash tanks

- Boosters for inhibition, ultrasonic cavitation, and rinsing

- Defoamers for wash and rinse tanks are often caused by removed soil that has a natural propensity to create foam, like some water-soluble materials.

KYZEN’s experienced technical staff provides friendly on-site support and process audits to help review your unique process and support your maintenance program. If the equipment isn’t operating at peak efficiency, then your yields are likely suffering. KYZEN’s unparalleled combination of proven maintenance products, process knowledge, and friendly support staff are here to help.