Circuit board assembly cleaning in a vapor degreaser has typically been a single-solvent process. However, following the recent ban of certain hazardous solvents commonly used in vapor degreasing such as nPB and TCE, there became a need for alternative solvents that were able to clean flux residue from electronic assemblies while being safe for the environment. KYZEN met this demand by creating DuoSolvent Cleaning.

What Is DuoSolvent™ Cleaning?

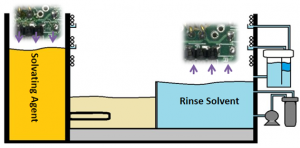

DuoSolvent cleaning is a waterless process that provides the benefits of vapor degreasing while overcoming health, cleaning, and material limitations. It was developed to utilize an existing cleaning process while providing superior cleaning results.

DuoSolvent got its name as the solvent cleaning process which incorporates two solvents:

- Solvent A: An engineered cleaning solvent that matches and removes a wide range of residues.

- Solvent B: An environmentally friendly, vapor degreasing solvent used in the rinsing stage.

Benefits of the Vapor Degreasing Process with DuoSolvent

- Parts come out of the process clean and dry

- No concentration monitoring

- No water maintenance or challenges

- Environmentally friendly

KYZEN Chemistries Recommended for DuoSolvent™ Cleaning:

KYZEN DS3522 – Solvent A

|

Solstice PF-2A – Solvent B

|