KYZEN can improve your cleaning efficiency with our specially formulated stencil cleaners, which will improve process yields. Most solder defects, some estimate up to 70%, can be attributed to the stencil printing process.

A clean stencil can be critical

As PCB assemblies become denser and miniaturization drives electronic component size ever smaller, the more important it has become that solder paste deposits and volume transfer are consistent and reproducible from board to board in the printing process. A number of factors can negatively affect these important attributes.

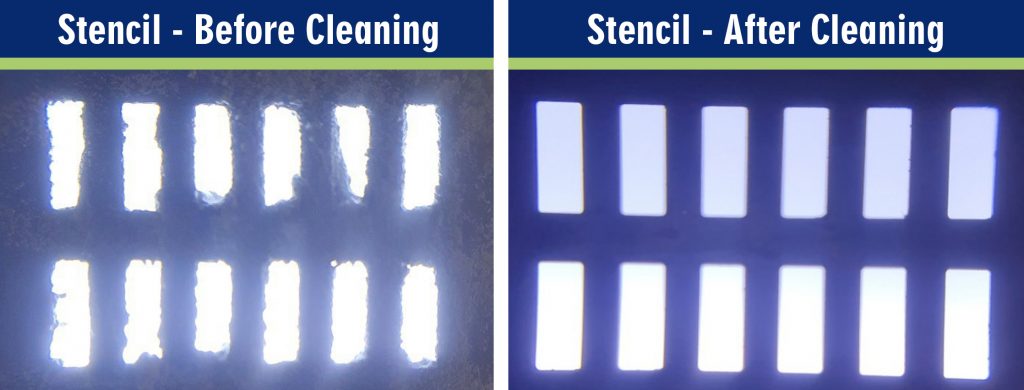

For example, proper solder paste transfer efficiency is especially critical for small pad features, because it reduces defects due to poor solder joints. In this case, solder paste builds up onto the aperture walls and bottom side of the stencil over time leading to insufficient or inconsistent transfer onto the pads. Periodic cleaning of the built-up paste with a KYZEN cleaning fluid designed for your application will improve print quality and process yield.

Select the right cleaning chemistry

Choosing the best cleaning agent or stencil cleaner is a function of matching the right KYZEN material to your cleaning method and your cleaning equipment.

Stencil Cleaning Methods

Depending on your manufacturing process needs, choosing the best cleaning method can be key. Whether it is manual (hand wipe), on printer (under stencil wipe) or an off-line cleaning machine process, KYZEN will work with you to make sure you get the best solder print and placement.

Cleaning Agent Guide

KYZEN’s array of stencil and misprinted PCB cleaning products for stencils is specifically formulated for all common cleaning methods. The table below simplifies the selection process by matching the cleaning agent to the process.

| CLEANING METHOD | AQUANOX A8820 | AQUANOX A8830 | KYZEN E5631 | KYZEN E5631J | CYBERSOLV C8882 |

| On Printer Understencil Wipe | ✓ |

✓

|

|||

| Off-Line Stencil Cleaning Spray Systems | ✓ |

✓

|

|

|

|

| Off-Line Stencil Cleaning Ultrasonic Systems | ✓ |

✓

|

|

|

|

| Off-Line Manual |

✓

|

|

✓

|

||

| Off-Line Hand-Held Ultrasonic Cleaning |

✓

|

|

✓

|